DOUBLE-TUBE HEAT EXCHANGERS AND THEIR ROLE IN BIOGAS PRODUCTION

Double-tube heat exchangers (HE) are instrumental in various industrial sectors, such as food processing and oil refining. They are known for their high efficiency, compact designs and ability to handle a wide variety of substrates. Heat exchangers are also a core sub-system implemented in all anaerobic digester designs, and their working efficiency is critical to good facility performance. In this blog post, we will delve into the technology behind double-tube heat exchangers, focusing on Fitec's systems and their significance in the biogas industry.

What is a Double-Tube Heat Exchanger?

A double-tube heat exchanger, often referred to as a "tube-in-tube" or “shell-in-tube,” consists of two concentric tubes, one situated within the other. The space between the two tubes enables an uninterrupted flow of heated fluids, which allows heat to be transferred between the materials in the two pipes effectively.

Fitec designs its double-tube HE systems with a 4" inner tube for circulating the substrate and a 5" outer tube for the hot water and glycol solution. The inverse flow direction of the substrate (which moves down) and the heating water (which moves up) allows for the most efficient heat transfer possible.

How Does It Work in Biogas Production?

In the context of biogas production, double-tube heat exchangers heat the feedstock in order to establish a proper operating temperature for the biological system inside the digester. In some jurisdictions, the heat exchangers are required to meet pasteurization requirements.

Some digester designs opt for ‘in-wall’ or ‘in-digester’ heating systems instead of external double-tube systems. Though it might sound more efficient to heat the tank directly, the location of these systems is a serious disadvantage. Aside from being difficult to access in case of lost circuits, crusts can also form over the elements making these systems less and less efficient over time. Even when operating optimally, only the material that is in contact with the tank wall can be heated. External HE’s are more efficient at rapidly heating the digestate because all of the digestate is heated as it passes through. Heat levels can also be readily maintained for longer periods. With external HEs, there is much less maintenance associated with proper functionality, and the system is always fully accessible. This equipment is built to last—a win-win on all sides.

The Fitec Difference for Biogas Plants

Although double-tube heat exchangers share similar design and operation principles across the industry, Fitec equipment sets itself apart in more ways than one. Our systems are capable of handling high total solids, and, due to our manufacturing processes, are custom-built based on our self-cleaning systems.

High Total Solids

Our heat exchanger system includes the use of our high-solids piston pumps that are purpose-built for applications with materials of up to 25% total solids. This unique feature allows our systems to use a more energy-dense feedstock, returning more dollars in energy production. The slow movement within the system ensures high heat efficiency and transfer rates but also reduces wear, which is a common problem with highly abrasive materials like food waste and sand-laden manure.

Additionally, only one single pump is required to pass material through the heat exchanger and into the digester, which is another example of the efficiency of Fitec’s designs.

Custom-built

Many people are surprised to learn that Fitec heat exchangers are manufactured in-house with facilities located in Germany, Canada and the US to suit our clients’ needs. Managing the manufacturing process internally allows us to maintain quality control on a system that is designed to give owners and operators equipment specially made for our Self-Cleaning Digesters. Our heat exchangers are, therefore, more effective at handling the demands of our biogas systems, ensuring they last longer. Similarly, these custom-built systems boast the easy maintenance associated with Fitec’s equipment.

Containerized Solution

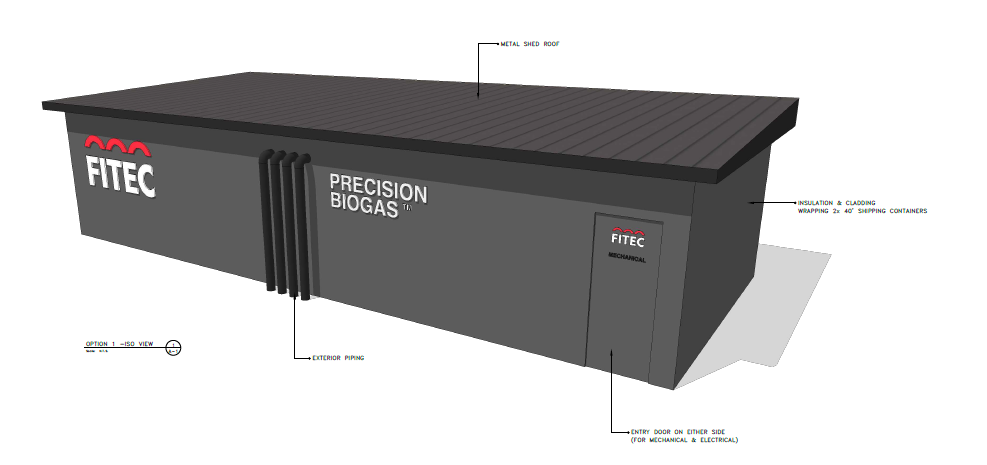

As a method for optimizing installation time, Fitec now offers the option of containerizing the heat exchangers. This allows our qualified and experienced technicians to assemble the necessary components at our headquarters in a plug-and-play setup that is easily shipped. Once the digester is operational, the containerized heat exchanger is delivered to the site and quickly integrated with the rest of the system.

A mock-up of the containerized solution for heat exchangers offered by Fitec.

Case Study: Villa Avocado

As a demonstration of our expertise, let's take a look at our recent project with Villa Avocado in Mexico, a global leader in food-grade avocado oil production. Our team was entrusted with creating a turnkey biogas plant for Villa Avocado, equipped with a double-tube heat exchanger tailored to their unique feedstock requirements. The challenge with this project involved keeping operational costs manageable while dealing with avocado pulp that has a high total solids of up to 22%.

In order to circumvent logistical challenges and meet strict deadlines, we designed a containerized heat exchange system for this project. This strategy enabled us to assemble the mechanical and system controls in Canada concurrently with the on-site construction work in Mexico. Rigorous testing ensured full operational efficiency before deployment. Once the system arrived on site, local installation time was greatly reduced.

Fitec's Double-tube Heat Exchangers Equipment and Services

At Fitec, we are committed to providing comprehensive and sustainable solutions for biogas systems. Fitec is at the forefront of delivering cutting-edge solutions in this field. Our advanced technology, customizability, and focus on efficiency and sustainability set us apart. As an integral part of our range of products and services, we include the meticulous design and installation of double-tube heat exchanger systems. Our goal is to design high-efficiency plants that are robust and reliable. When it comes to our HE, they are an integral part of our operationally efficient processes. If you would like to learn more about our services and solutions, reach out to us.